Portugal faces several challenges in waste sorting, crucial for effective recycling. Contamination of recyclable with non-recyclable materials reduces the quality and recyclability of collected waste. Public awareness is often insufficient, leading to improper sorting and disposal practices. In the context of Portugal's PERSU 2030 plan, which aims to achieve higher recycling targets and sustainable waste management, there is an urgent need to develop automatized and innovative sorting technologies to increase efficiency and the quality of recycled materials.

Upon arrival at the sorting facility, recyclables are first subjected to a pre-sorting stage to remove larger non-recyclable material. This initial step is crucial to ensure the purity and quality of the sorted materials. Advanced technologies such as ballistic and optical separators are then employed. Ballistic separation uses mechanical processes to sort materials based on their physical properties, while optical sorting leverages high-resolution cameras and sensors to identify and categorize recyclables by type and composition using AI algorithms. These systems can distinguish between different materials like different types of plastic and metal. The sorted materials are then compacted into bales for easy transportation to recycling facilities.

To increase the efficiency of waste packaging sorting, we seek innovative solutions that address the core challenge.

The following issues are some examples of processes that could be improved:

- Characterization of Incoming Material Loads: Develop methods to accurately characterize and quantify the percentage of contamination in received waste streams.

- Improved Identification and Separation Capabilities: Enhance the ability to identify and separate various materials such as Film, PET, thermoformed PET, HDPE, PP, LPB (Liquid Paperboard packaging), Aluminium and other plastic packaging.

- Efficiency of Automatic Separation: Boost the efficiency of automatic sorting systems, particularly on conveyor belts with high material overlap.

- Automation of Quality Controls: Strengthen the automation processes for quality control to ensure better sorting outcomes.

Valorsul is planning to build new facilities, so solutions beyond the scope of these specific problems are also welcome.

- New ways of characterizing packaging waste and contamination.

- Solutions to increase efficiency and purity through automated separation of packaging waste.

- New ways of automatically separating packaging waste and contaminants.

- Development of pilots that allow easy integration into Valorsul's current processes.

- For solutions that cannot be developed in Valorsul’s facilities, the pilot may be carried out outside Valorsul's facilities if the operational conditions are similar and the results of the pilot would be the same as if the solution was developed at Valorsul's facilities.

- The solution to be implemented must comply with current legal requirements.

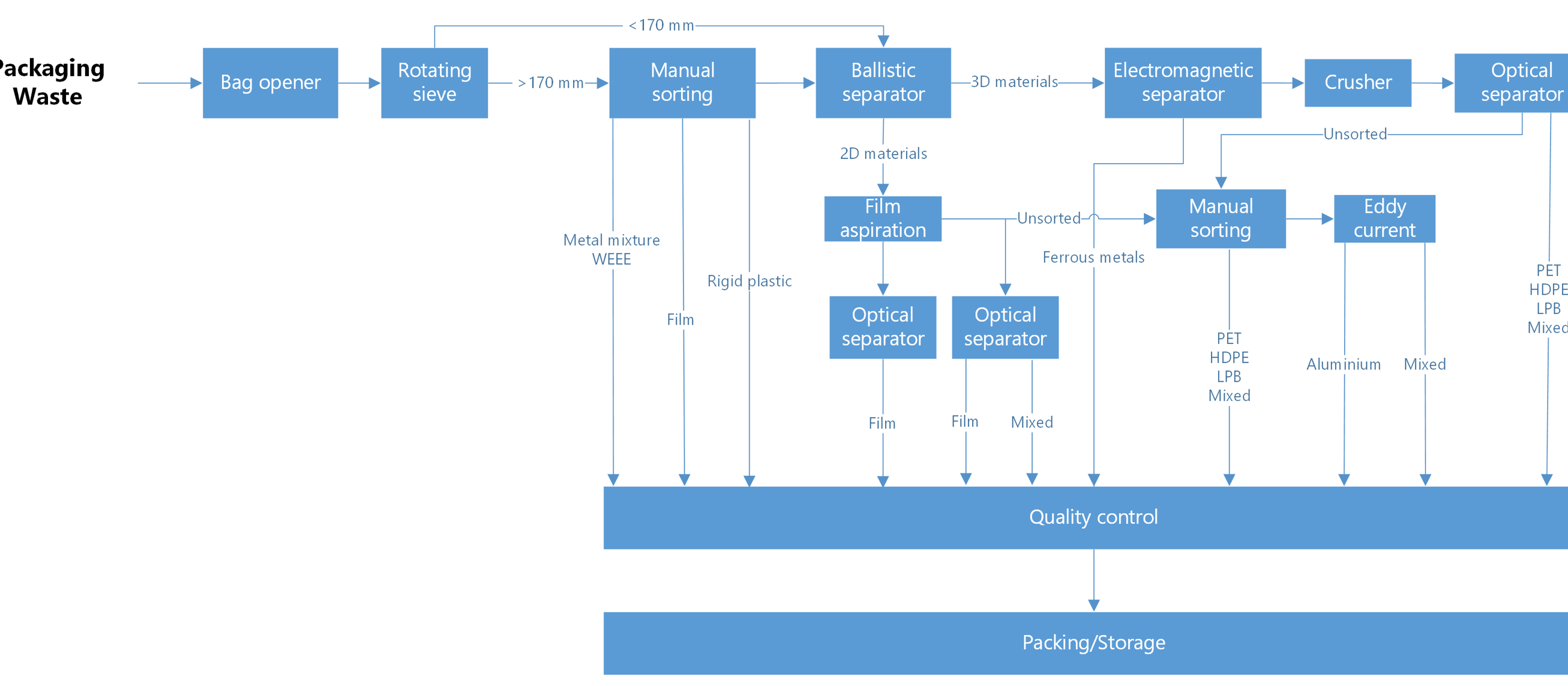

Upon arrival at Valorsul’s sorting centre, the packaging waste goes through a bag opener and a sieve, where the first separation between higher (>170 mm) and lower (<170 mm) dimension material occurs.

The higher dimension material goes directly to manual screening stations, where it is separated between different fractions: film, rigid plastic and non-packaging metal mixture materials.

The remaining material is directed towards the ballistic separator, which also receives the lower dimension material from the sieve separator (<170 mm).

In the ballistic separator the material is divided into three fractions: (1) the refused material – composed by fine and small materials; (2) the 2D materials; and (3) the 3D materials.

The 2D materials are directed towards a film aspiration system and then to optical separation – resulting in film and mixed fractions submitted to manual quality control; the unsorted materials are directed towards manual sorting and then to non-ferrous metals extraction.

The 3D materials from the ballistic separator goes through a magnetic plate to extract ferrous material and the remaining material is crushed and directed towards optical separators, creating different streams: PET, HDPE, LPB (Liquid Paperboard packaging) and mixed materials; the unsorted materials are directed towards manual sorting and then to non-ferrous metals extraction.

All streams are submitted to a manual quality control step before going to the packing and storage station. The sorted materials are then compacted into bales for easy transportation to recycling facilities.

Apply here.